FLAP DISCS

Choose the ideal flap disc!

Whereas in the past a single type of disc was used to work all types of materials and workpieces, Cibo now offers a product range of specific flap discs with very distinct properties.

Overview of Cibo's flap discs

All our blade discs are made in-house, allowing us to guarantee the highest quality.

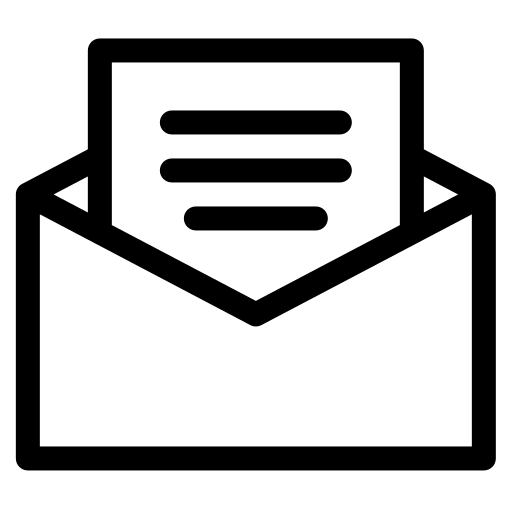

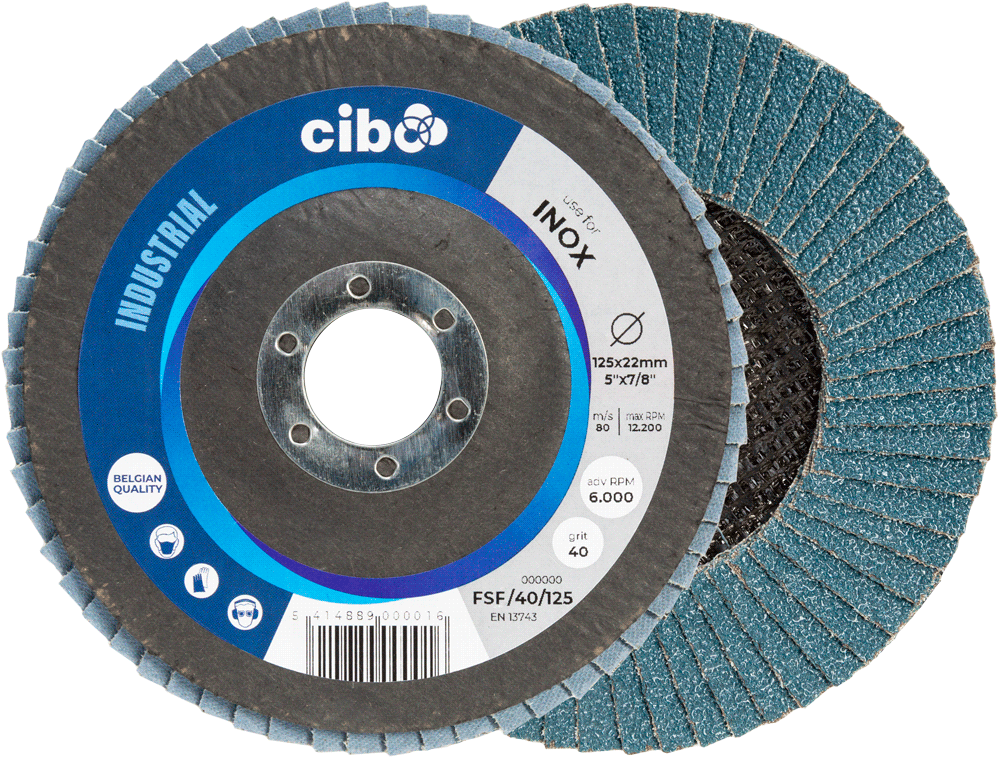

Industrial

Inox

Machining

The Industrial inox disc is the perfect entry-level disc for working stainless steel.

product codes: FSC, FSF

More infoOrder here

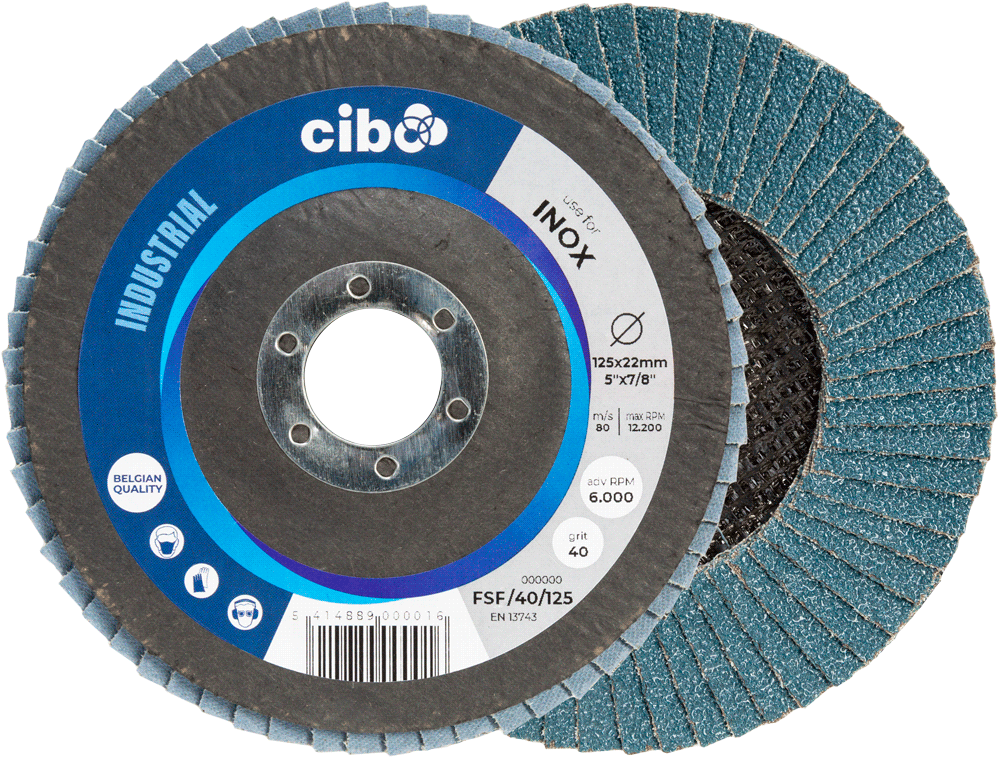

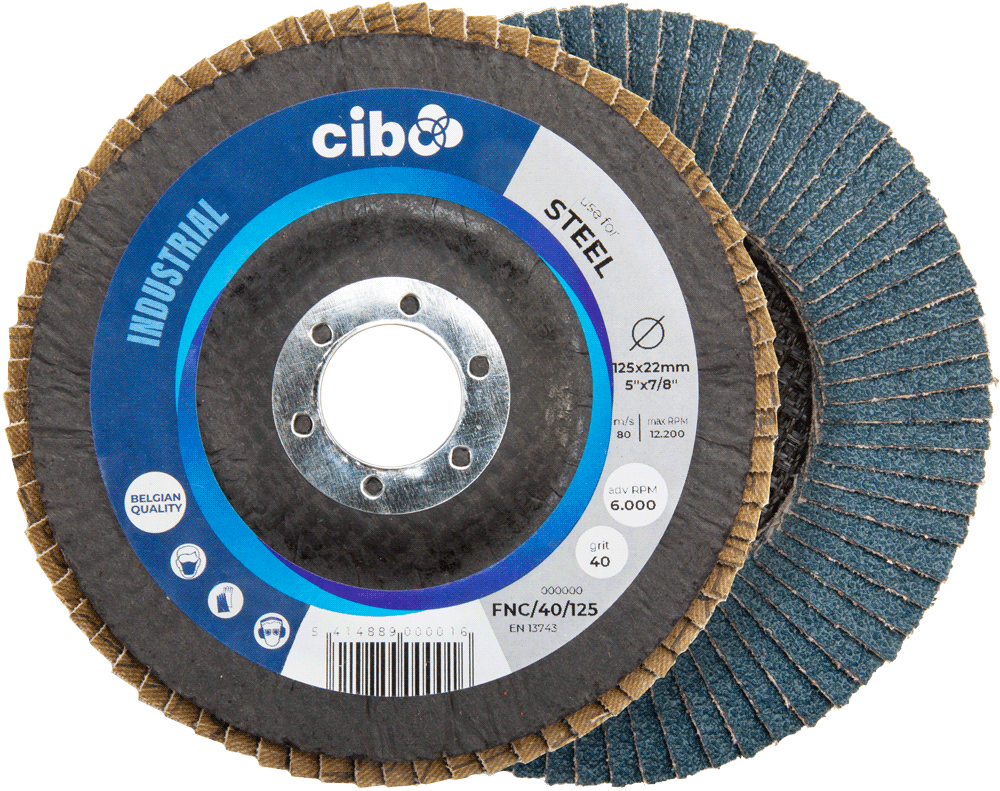

Industrial

Steel

Machining

The Industrial disc for steel uses the same high-quality abrasive grain as the stainless steel variant but has a slightly stiffer poly-cotton backing.

Product codes: FNC, FNF

More infoOrder here

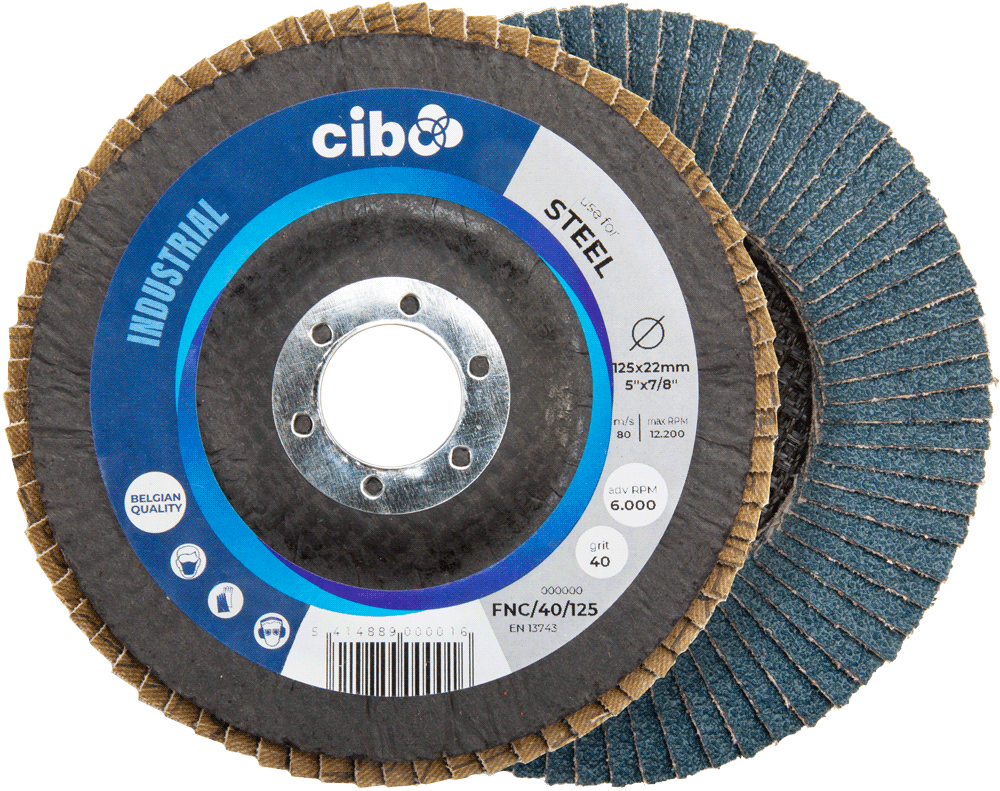

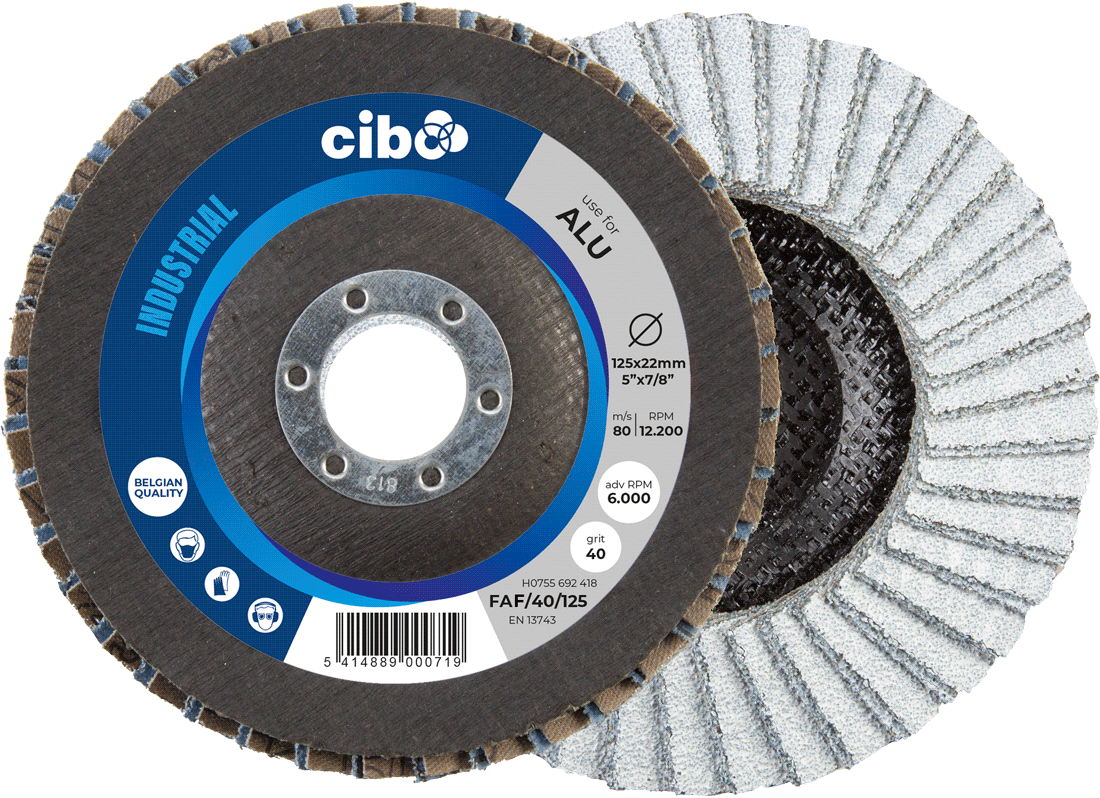

Industrial

Aluminium

Machining

Our Industrial flap disc is specially developed for effortless and efficient grinding of aluminium.

More infoOrder hereProduct codes: FAF, FAC

Performance

Machining

The Performance disc is a versatile all-rounder with ceramic grit for fast, cool grinding and long life.

Product codes: FPF, FPC

More infoOrder here

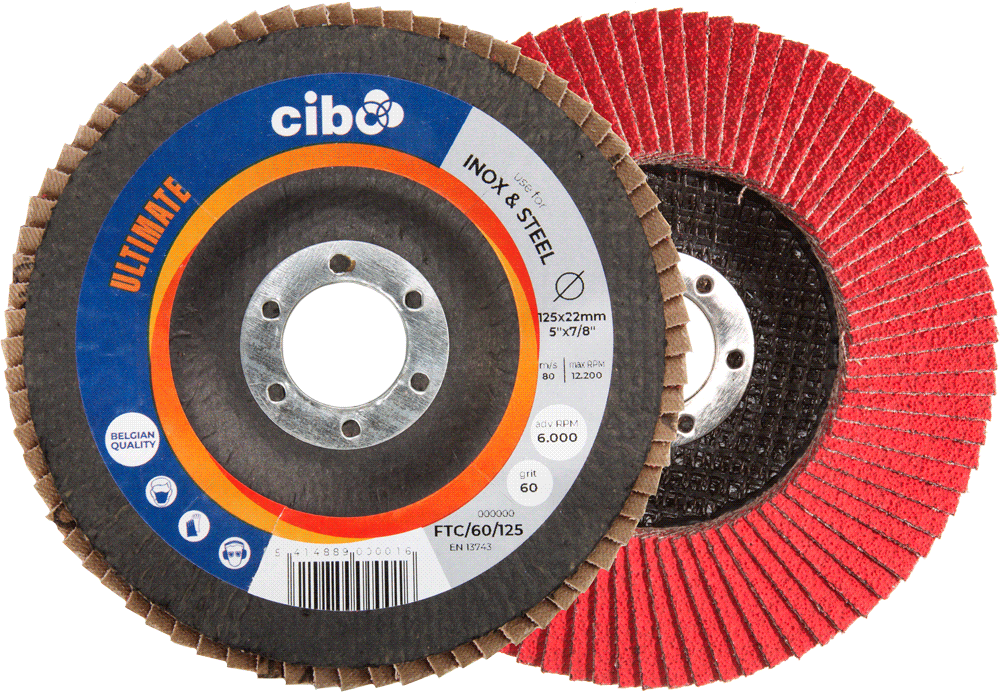

Ultimate

Machining

The Ultimate disc is the highest machining flap disc available on the market.

Product codes: FTC, FTF, FOV

More infoOrder here

RCD

Machining

Finishing

With the RCD flap disc, you can grind away a stainless steel weld seam in 1 step and finish it flawlessly.

Product codes: RCD

More infoOrder here

LVT

Finishing

This disc is perfect for creating an even finish and improving surface quality.

Product codes: LVT

More infoOrder hereMachining flap discs

Machining

Inox

Industrial - Inox

Best efficiency at low pressure

The Industrial stainless steel flap disc is the perfect entry-level disc for working stainless steel. Thanks to the specially developed flexible linen, this disc achieves high efficiency immediately and even at lower pressure.

In combination with the high-quality 100% zirconium grit, the Industrial inox disc ensures the best efficiency with low pressure and less powerful 750-watt machines.

Product codes: FSC, FSF

Machining

Steel

Industrial - Steel

Much longer lifespan

The Industrial flap disc for steel uses the same high-quality abrasive grain as the stainless steel variant but has a slightly stiffer poly-cotton backing. This backing was specially developed for flap discs, resulting in a lifetime almost twice as long compared to a classic flap disc.

The poly-cotton carrier performs best at slightly higher pressure and ensures a constant wear pattern. The result is constant machining from start to finish.

Product codes: FNC, FNF

Machining

Aluminium

Industrial - Alu

3x longer lifespan

Our Industrial flap disc has been specially developed for efficient machining of aluminium and other soft alloys. Thanks to the use of high-quality zirconium linen combined with a stearate coating, the disc is effectively prevented from clogging - a common problem in aluminium machining.

The stearate coating prevents aluminium from adhering to the disc, keeping the abrasive grains active for longer. As a result, the disc maintains its abrasive capacity and a consistent finish is guaranteed, even during prolonged use.

Product codes: FAF, FAC

Machining

All-rounder

Ceramic

Performance

The versatile all-rounder

The Performance flap disc is one of the most versatile discs in the world. Thanks to its ceramic abrasive grit, any metal can be worked on in record time. This disc combines the aggressiveness and durability of the Ultimate line with the ease of use of the Industrial line.

It makes the Performance disc the dream all-rounder for top performance. The ceramic top coating makes this disc much cooler to sand. This extends the lifetime and prevents sticking to softer materials.

Product codes: FPC, FPF

Contact

Can't find exactly what you are looking for? At Cibo, customisation comes as standard. Get in touch and we will be happy to help.

Heavy machining

High pressure

Ceramic

Ultimate

The best disc for heavy stock removal

The Ultimate flap disc is the highest machining flap disc available on the market. Thanks to the specially constructed ceramic grit, this disc ensures the highest stock removal rate at high pressure. So it is the ideal disc for heavier work, such as in shipyards, bridge builders, railways, energy sector,...

Product codes: FTC, FTF, FTPC, FTPM, FOV

This disc also exists with M14 connection for a quick disc change without flanges.

Machining

Inner corners

Heavy-duty machining in every corner

Discover the FOV Ultimate disc

Specially made for inner corner grinding

The flaps in an extended flap disc are placed in such a way that they ‘extend’ onto the carrier more than in a standard flap disc. The main benefit of this type of disc is that seam in a corner profile. The position of the flaps eliminates the risk of damage because direct contact between the carrier and the workpiece is avoided.

The extended flap disc is the ideal option for heavy machining in an inside corner

The extended flap disc is the ideal option for heavy machining in an inside corner

Comparison table for machining flap discs

Header 1

|  |  |  |  |  |

Machining |  |  |  |  |  |

Lifespan |  |  |  |  |  |

Finishing

|  |  |  |  |  |

Recommended power output | from 750 W | from 750 W | from 1000 W | from 1200 W | from 1200 W

|

Grain | 100% zirkonium

| 100% zirkonium

| 100% zirkonium

| zirkonium + ceramic | ceramic |

Backing | linen | polycotton

| fibreglass

| polycotton

| polycotton

|

Top coating

| no | no | yes | yes | yes |

Pressure | low | medium

| medium

| high | high |

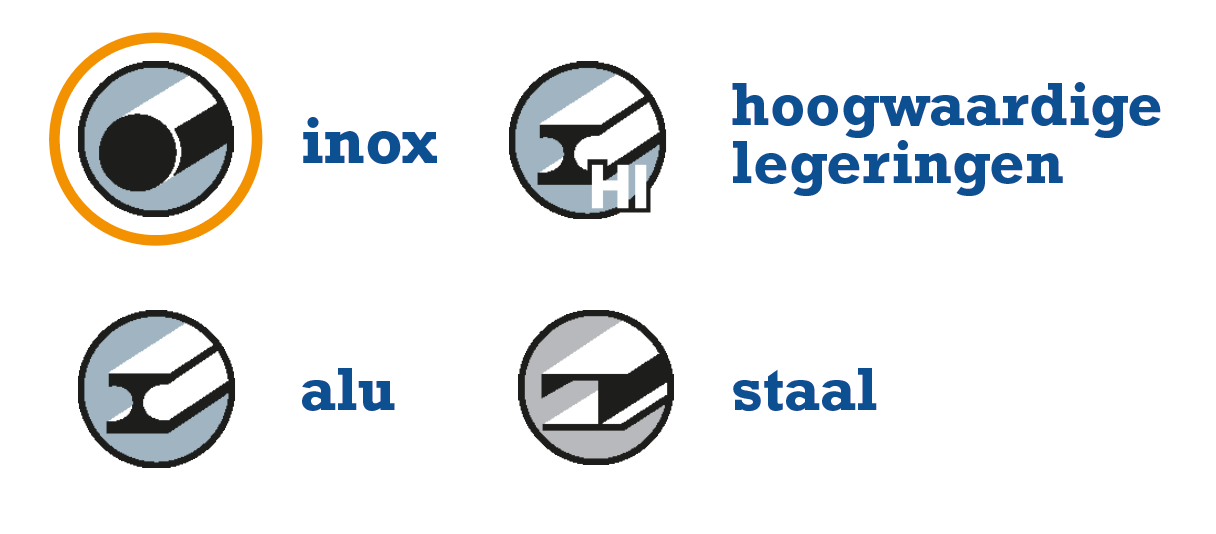

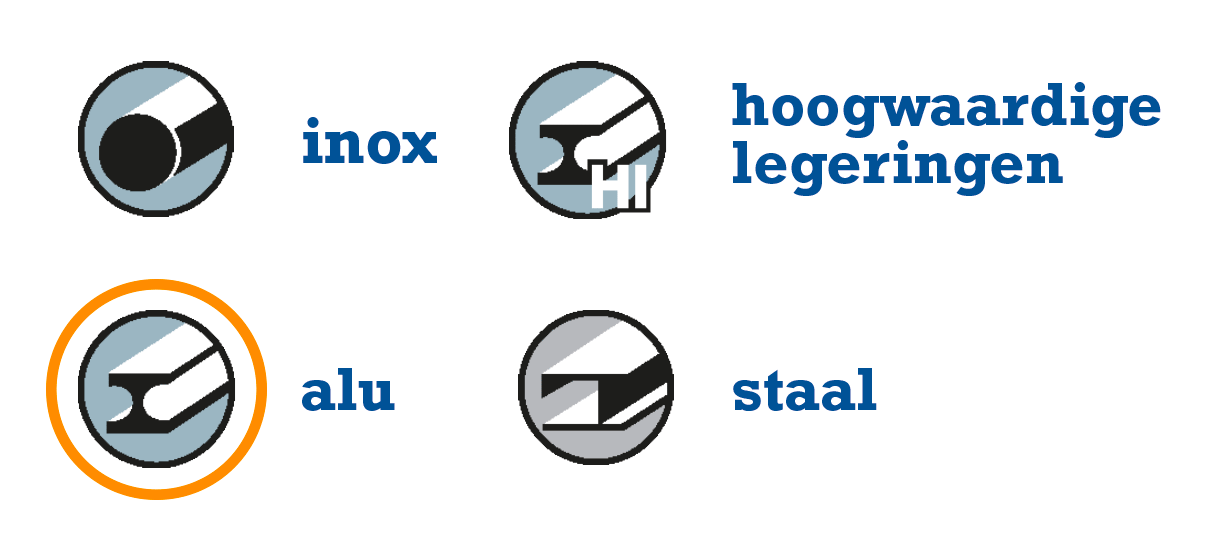

Suitable for |  |  |  |  |  |

Flap discs for finishing

Machining

Finishing

Grind and finish weld seams in one step with the RCD

This revolutionary Cibo innovation is composed of 2 complementary abrasives that together achieve brilliant results in 1 step.

Where previously an experienced grinder needed at least 3 steps to completely remove a weld seam, an inexperienced user now completes the job effortlessly in just 1 step!

Finishing

Allrounder

The LVT flap disc for a smooth, even finish

The LVT flap disc is a reliable all-rounder for finishing your workpiece.

Ideal for creating a smooth finish and improving surface quality.

This disc is perfectly suited for general applications where a clean and consistent finish is desired. A smart choice for daily use in workshops and production environments.

The perfect companion

The Finipower Plus

The Finipower Plus is the all-rounder among machines.

Order hereMore infoThanks to its wide speed range, this angle grinder is the ideal partner for all your sanding and grinding tasks.

It’s the perfect grinding tool to get the most out of our flap discs and RCD finishing discs.

Made by professionals,

for professionals

In-house ontwikkeld, getest en geproduceerd

At Cibo, we manufacture all our flap discs entirely in-house, within our own production facility. This way, we maintain maximum control over quality, performance, and delivery reliability. No compromises, no middlemen — just genuine expertise and innovation, straight from the source to the user.

Frequently asked questions - FAQ

What is a flap disc and what is it used for?

A flap disc is a disc with overlapping flaps of abrasive material, ideal for grinding, sanding and finishing metal, wood and plastic surfaces.

Which flap disc do I need for metal?

For metal, a flap disc with zirconium or ceramic alumina is usually used. These are wear-resistant and suitable for heavy-duty work such as removing rust or finishing welds.What is the difference between a flap disc and a grinding disc?

A flap disc has overlapping flaps and lasts longer than a regular grinding disc. Additionally, a flap disc grinds more efficiently thanks to the continuous exposure of fresh abrasive material.How do I choose the right grit size for my flap disc?

Use a coarse grit (P40–P60) for aggressive material removal, and a finer grit (P80–P120) for a smooth finish. The choice depends on the material and the desired surface finish.What are the advantages of a zirconium flap disc?

Zirconium flap discs stay sharp during use and are well-suited for working on hard metals such as stainless steel or steel.How to work safely with flap discs?

Always wear safety goggles, hearing protection, and gloves. Make sure the flap disc is securely attached, and run it briefly at idle speed first to check for imbalance.More information

The Cibo team is there for you

Cibo is at your service with expert advice on sanding, grinding and polishing.

Ask an expert!