Orthopaedic & medical

Perfect finishing of orthopaedic implants and instruments

Consistent results thanks to innovative processes

The art of finishing

The medical industry is becoming increasingly demanding, which means that the quality standards for finishing are becoming ever stricter. This also applies to implants and surgical instruments, which are often finished completely, right up to the sterilization process.

To meet the stringent requirements of the orthopedic industry, a manufacturer needs a partner with unique expertise in grinding and finishing.

With 75 years of experience, Cibo is the trusted specialist in this field.

Applications in the orthopedic world

Deburring

Deburring is required for almost all orthopedic components that come into contact with bone, tissue, or other implants, as well as for instruments where precision and safety are essential.

Finishing and polishing

Polishing and finishing in the orthopedic field are essential for patient safety, the functionality of implants and instruments, their durability, and optimal hygiene.

Specific applications

Application

Removing scratches and correcting sanding errors, pre-polishing

Scratches, casting defects, or excessive heat during finishing can slow production, lead to rework, or increase costs.

Our unitized S-line delivers the ideal balance of power and control, with low heat generation that protects even the most complex geometries.

Effortlessly remove scratches, casting errors, and fine weld seams, and achieve a smooth, high-gloss finish that meets the strictest medical standards, every time.

Application

Removing milling lines and welds, deburring

Stubborn milling lines, welds, or burrs can damage surfaces and require additional rework. Our unitized M-line provides the ideal solution. More aggressive than the S-line, it quickly and precisely removes milling lines, light weld seams, and burrs without generating excessive heat.

Order hereMore info M-lineThanks to its flexible design, the M-line adapts to complex shapes while maintaining full control over the finish.

Our products specifically for the orthopedic and medical field

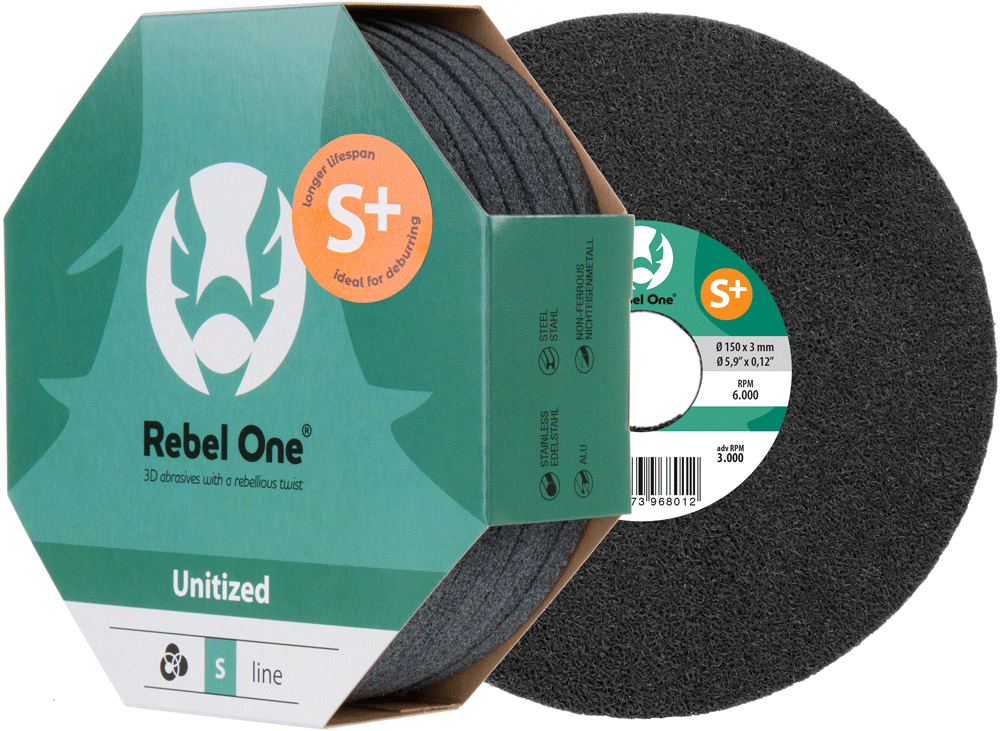

Rebel One Unitized

S+

Removing scratches and correcting sanding errors, pre-polishing

Order hereMore info S-line100% Belgian

Rebel One Unitized

With over 75 years of experience, we proudly consider ourselves experts in sanding, grinding, and polishing, including within the orthopedic and medical industries.

Rebel OneOur products, especially our Rebel One Unitized line, are used for finishing orthopedic and surgical instruments such as forceps, scissors, hip implants, knee prostheses, surgical scalpels, and blades.

Manufactured with the utmost precision in our own facility in Belgium, they not only meet the strict standards of the medical field but also help shape these high standards.

Advantages Rebel One Unitized

Longer lifespan & reduced heat generation

Consistent & high-quality finish

Strong density yet flexible and forgiving

100% in-house production and fast worldwide delivery

Free from animal derivatives & solvents

All our unitized products are completely free of animal products, by-products, or derivatives.**

Their composition consists entirely of synthetic, mineral, and plant-based materials. In addition, our entire unitized range is 100% solvent-free.

75+ years of experience

Why choose Cibo?

To meet the strict standards of the orthopedic industry, you need a partner with unique expertise in sanding and finishing

Cibo offers specialized sanding solutions for the orthopedic industry, built on over 75 years of experience in sanding and finishing applications.

They provide precision and reliability for critical tasks such as deburring, polishing, and finishing complex surgical instruments and implants.

News

Med Tech Outlook:

"The Rebel One unitized products from Cibo Abrasives are quickly becoming the preferred grinding wheels in various medical manufacturing processes, used for working on titanium, stainless steel, and other special alloys with the finest detail."

Custom solutions for specific challenges

Every orthopedic implant and surgical instrument presents its own unique challenges. Thanks to our extensive experience, we can provide tailor-made solutions that perfectly meet your needs.

Contact us and let us demonstrate our expertise.

Contact

Our grinding expert in the orthopedic industry

ContactOther industries in which Cibo is active

Marina construction

More information

The Cibo team is there for you

Cibo is at your service with expert advice on sanding, grinding and polishing.

Contact