RCD FLAP DISC

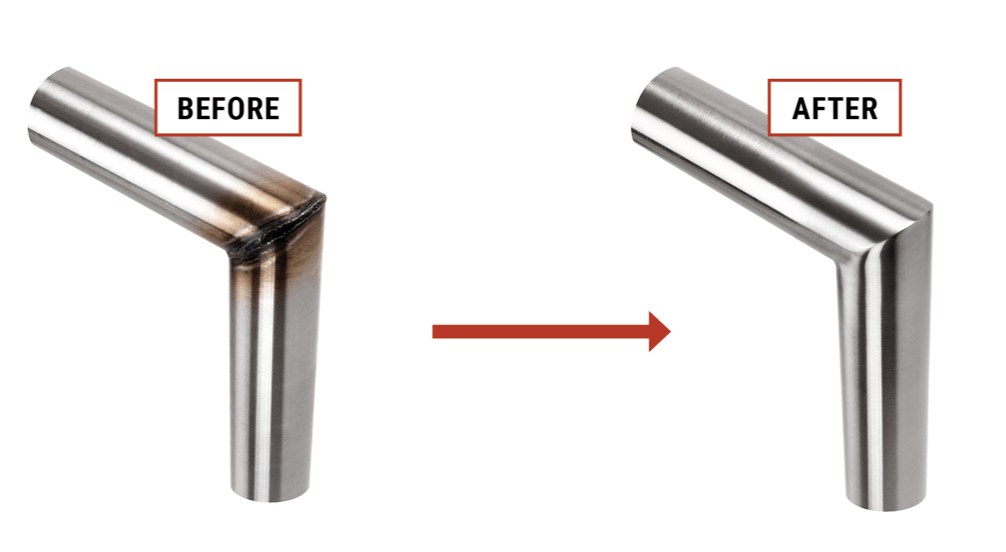

Grind and finish stainless steel in one simple step

The RCD disc is a unique flap disc that serves as both a machining and finishing disc. Use the Cibo RCD disc to grind down weld seams and create a flawless finish in a single pass.

Three tasks in one

In the past, a skilled grinder needed at least three passes to get a good finish. Now, with Cibo’s patented tool, even an inexperienced user can get the job done in a single step.

It takes just one operation to grind off an RVS weld seam and create a flawless finish.

Save on time, save on costs – and get a better finish! Are you ready to make savings on time and labour, without compromising your perfect finish?

Cibo has the solution for you: our revolutionary patented RCD disc!

Current three-disc method

Step 1

Grind with a grit 60 flap disc to remove the weld seam.

Step 2

Regrind with a finer grit (80 or 120).

Step 3

Final pass with a reinforced Tex flap disc to get the finish.

Risks of the current 3-disc method

If you try and work too quickly, the coarse grit may create deep grooves

There is always a risk of scoring the material

Your corners can end up too rounded; you’re grinding facets

If you keep grinding for too long, you produce heat

If you want to work too quickly and therefore choose a grain that is too coarse, you run the risk of removing too much material

To fix this, you need to skilfully try to restore the geometry or weld it back together, which takes extra time

This working method requires experience and a great deal of skill to achieve a good result

Our RCD is the solution

With the RCD disc, you don’t just grind off the RVS weld seam in a single operation; you also get a clean finish. The two complementary abrasives work together for a superb result, and all it takes is a single pass.

Video

How to finish stainless steel in just one step?

RCD applications

Finishing light weld seams

Finishing corners and toothing

Improving surface roughness

Refining coarse sanding lines

Breaking sharp edges

Removing scoring

Grinding down casting defects

Homogenising surfaces

Pre-polishing

Removing weld spatter

Elimination of milling lines

Suitable for

Metal

Stainless steel

High-quality alloys

Non-ferrous metals

Aluminium

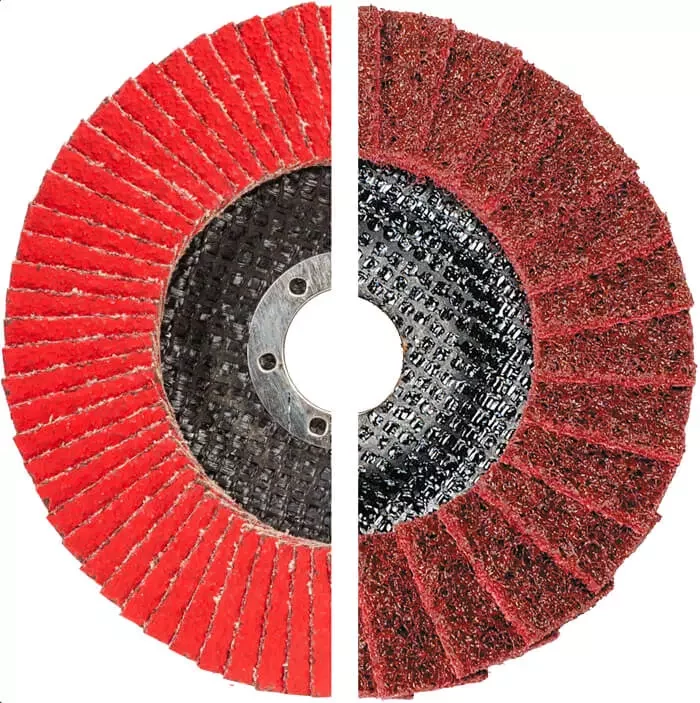

What makes the RCD so unique?

Cibo's unique combination of two abrasives, each with its own special properties, makes a product where two and two make at least five

The RCD is made of polycotton abrasive cloth. That makes it extra-flexible, yet powerful thanks to the grinding aid. In addition, the surface conditioning and the abrasive cloth ensure it grinds evenly. This gives you elasticity and a shock-absorbing effect during grinding. Precision work and ease of use guaranteed!

All our discs are produced in Belgium and meet the highest quality standards.

Advantages of the RCD

Controlled stock removal: you don't create pits or remove too much material

Forgiving disc: the soft contact and controlled removal eliminate any risk of damage

Uniform finish: this translates into a low, consistent Ra value

Lower heat production: no discolouration on the workpiece

Huge time savings: just one operation instead of three means a lower cost price

Versatile: stainless steel or aluminium, woodwork or metal chassis... there’s an RCD for every type of material

Environmentally friendly: the unique composition means less loss and less waste

Tips & Tricks

Grind from front to back with a brushing motion, rather than across the seam

Grind at an angle of 30 degrees, rather than 45 degrees

Reduce the speed from 10,000 rpm to 3,000 rpm for best results!

Range

RCD finishing discs

Do you want a combination of a high-quality and uniform finish coupled with controlled material removal? If so, use this finishing disc, with the Quick Change mechanism as a small and extremely adaptable variant. Ideal for finishing angles, reducing surface roughness, breaking edges,...

These discs can be put to use for a wide variety of purposes: stainless steel, aluminum, soft metals, special alloys,...

Glass Fibre Backing

Type

: conisch

More infoDiameter:

⌀ 115 - 125 - 180

(4-1/2” x 7/8” - 5 x 7/8”)

(4-1/2” x 7/8” - 5 x 7/8”)

Grain (type):

VF - ME - CO (Aluminium oxide)

RCD Grinding Disc

Heavy grinding and finishing at the same time? Yes, it's possible! With RCD Extra and Ultra Coarse you are holding onto a very aggressive disc thanks to the ceramic cloth, while the surface conditioning between the ceramic flaps limits the grinding depth. The dampening function of the surface conditioning flaps guarantees a greater amount of control during grinding.

Glass Fibre Backing

Type

: conisch

More infoDiameter:

⌀ 115 - 125

⌀ 115 - 125

(4-1/2” x 7/8”)

Grain (type):

UX - UC (Ceramisch)

Handy!

Maximize your RCD disc performance with the Finipower Plus!

The Finipower Plus is the all-rounder among the machines. Given its wide rpm range, this angle grinder is ideal for all your sanding and grinding work.

Finipower PlusIt can be used in combination with our Rebel One unitized range, our flap discs and our RCD finishing discs.

More information

The Cibo team is there for you

Cibo is at your service with expert advice on sanding, grinding and polishing.

Contact