Tank manufacturing

The future of tank manufacturing

Time-saving abrasives, developed for consistency and reliability in the tank manufacturing industry

Specific applications in tank manufacturing

Application

Finishing tank walls and tank heads

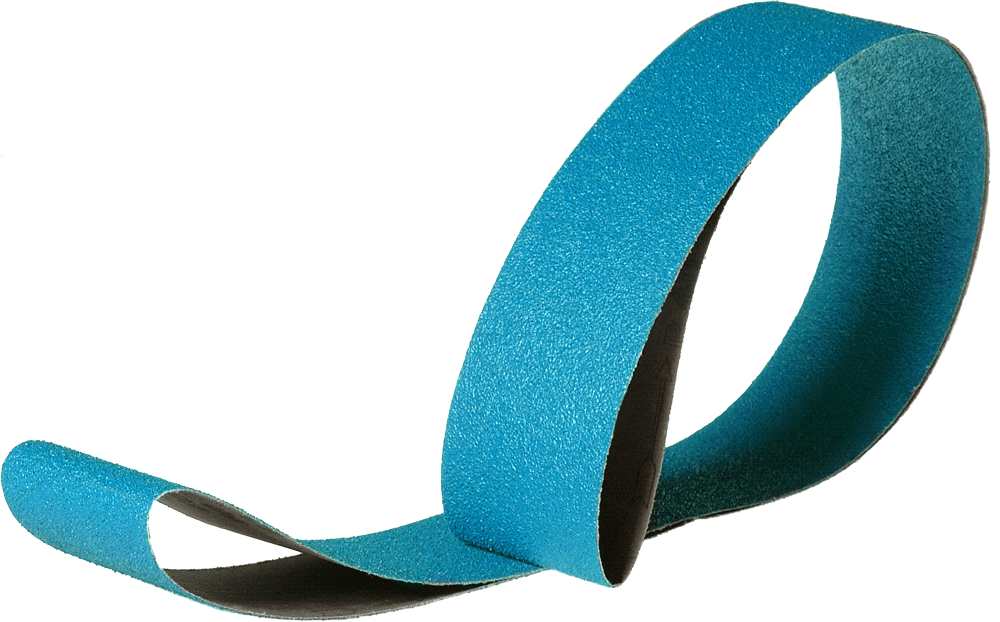

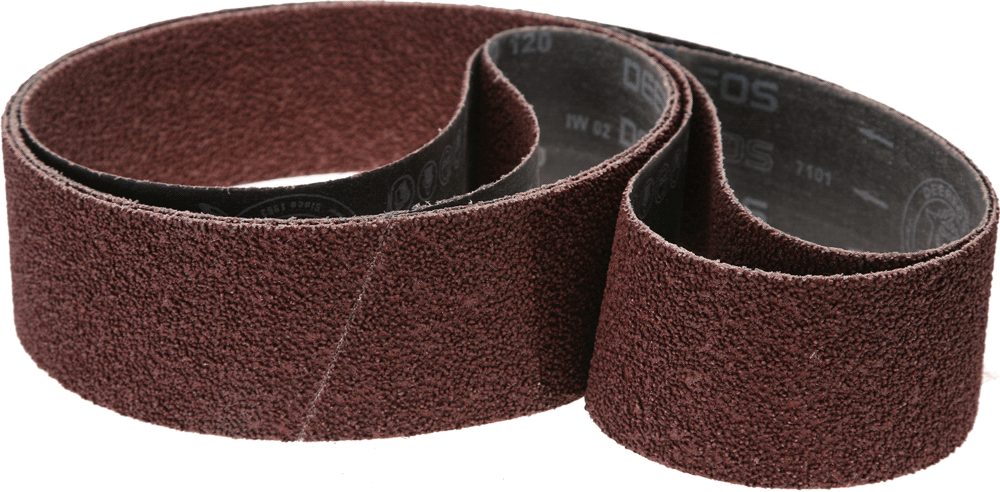

For the finishing of tank walls and heads Cibo offers a wide range of abrasive belts, ensuring a smooth transition through the different phases of the finishing process, from rough machining to fine polishing. Thanks to our longstanding experience in abrasive belt production, we can guarantee a consistent

finish, while saving you time and money. This consistent finish is essential for fabricating tanks from steel/stainless steel, non-ferrous metals or composites.

Furthermore, we have an extensive selection of grit types and sizes, backings, and belt sizes: whatever your material and the required finish, we’re sure to have the perfect match.

Furthermore, we have an extensive selection of grit types and sizes, backings, and belt sizes: whatever your material and the required finish, we’re sure to have the perfect match.

Our products specifically for finishing tank walls and tank lids

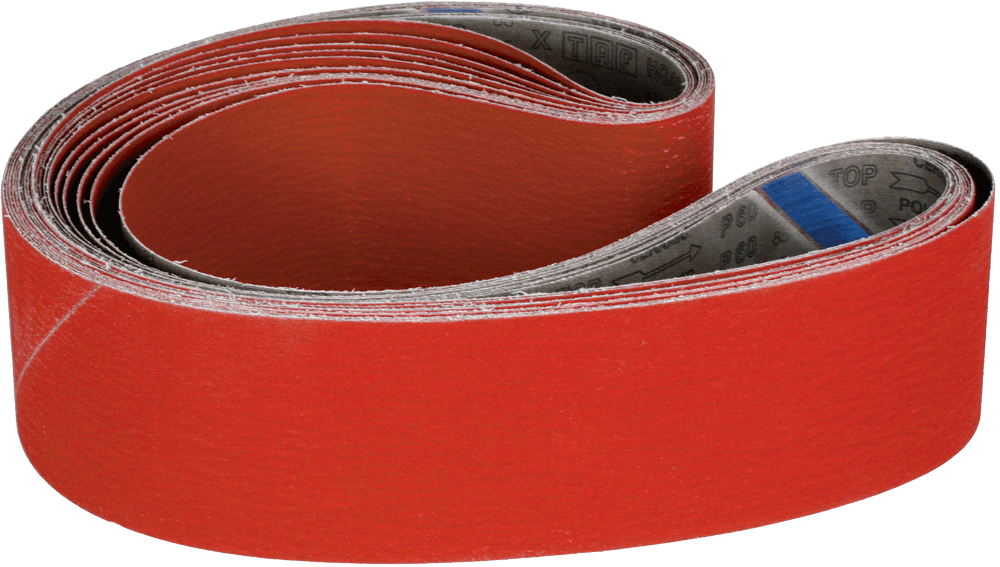

Ceramic

FX87

The FX87 is a very aggressive grinding belt, perfect for quickly removing heavy welds without overheating.

Order here

Ceramic

AK890

The AK890 is the most aggressive and fast-cutting belt in Cibo's range, perfect for quickly removing heavy welds without overheating.

Order here

Compact grit

KK718

With the KK718 belt, you can grind with precise control to achieve the desired surface roughness, with consistent performance.

Order here

Reinforced tex belts

FE

Used for visual finishing, removing light scratches, and creating a smooth surface. Especially suitable when deburring is still required.

Order here

Reinforced tex belts

RC

Ideal for visual finishing; removes light scratches and creates a smooth surface with a perfect finish. Primarily used for high-quality final finishing.

Order hereApplication

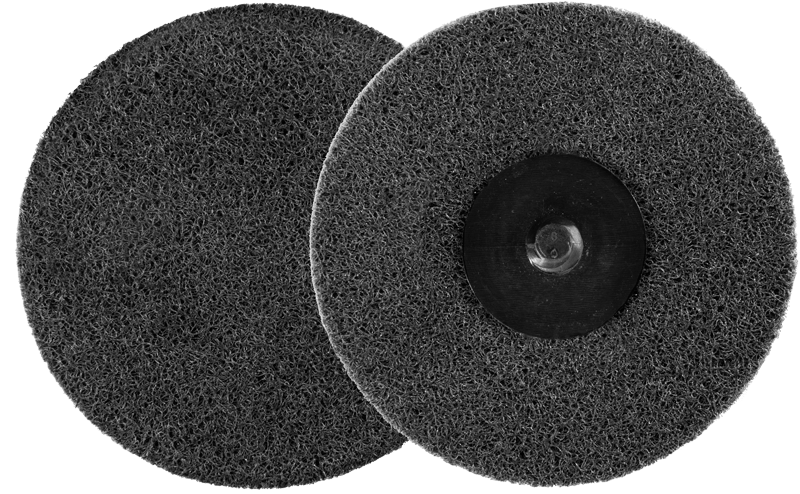

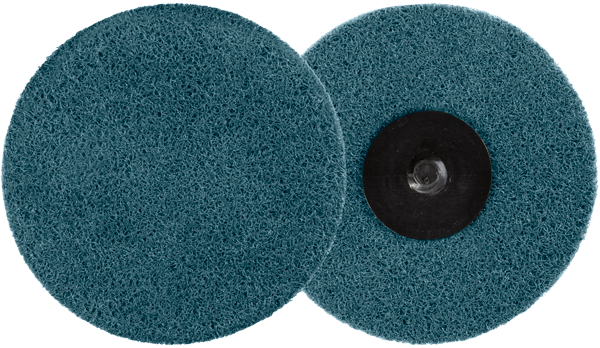

Weld finishing in hard-to-reach areas

In hard-to-access areas, such as pipe joints, inside corners, or flanges, weld finishing requires flexibility and precision.

Cibo’s unitized abrasives combine form retention with controlled material removal, without risking deformation of the workpiece. Ideal for a clean, safe, and reproducible finish, even in the most challenging zones.

Products for finishing welds in hard-to-reach areas

Quick Change

Unitized

S-line

QLSA+

The QLSA+ quick-change disc is ideal for removing light burrs and rounding edges.

Unitized

T-line

TA

The TA wheel is an aggressive and very hard-quality product, offering fast and controlled material removal with an acceptable finish.

Order hereMore about T-lineApplication

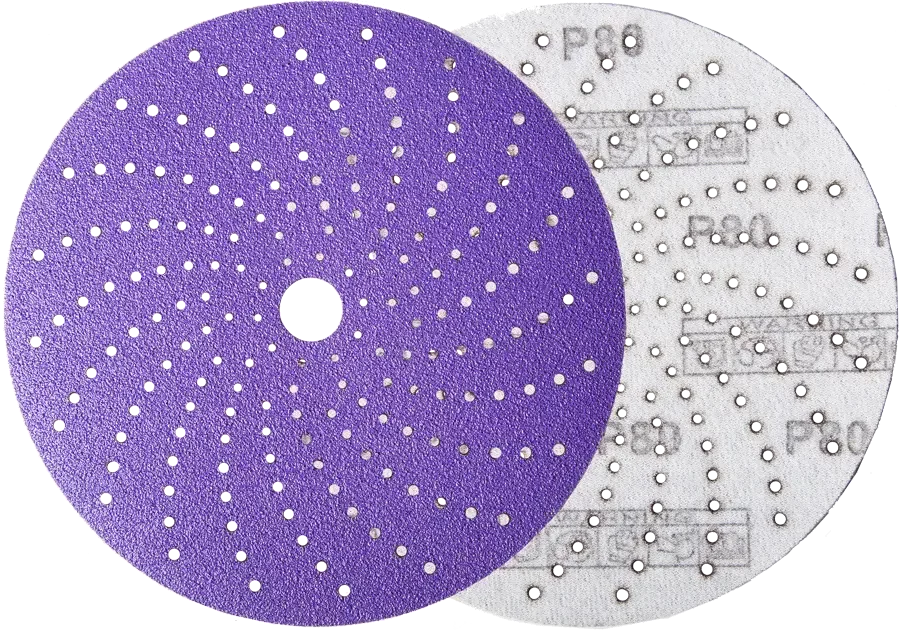

Preparing for paint and coating applications

Good paint adhesion starts with perfect surface preparation. For optimal adhesion of paint or coating, a uniform surface roughness is essential, whether for large areas or spot repairs.

Thanks to their ease of use, quick change capability, and reliable performance, grip and quick-change discs are an indispensable part of any painting process.

Products for paint and coating preparation

Inox

Steel

FCGR

The FCGR grip disc is coated with ceramic grains on a film backing, providing optimal aggressiveness and stiffness.

Order here

Composite

330GR

The 330GR grip disc is specially designed for light sanding of polymer or composite surfaces.

Order here

Unitized

X-lijn

QLXA

The QLXA is a compact unitized quick-change disc for localized repairs and preparatory work in small areas. (Available in 50/75mm)

Order hereExplore our other innovative products for tank construction

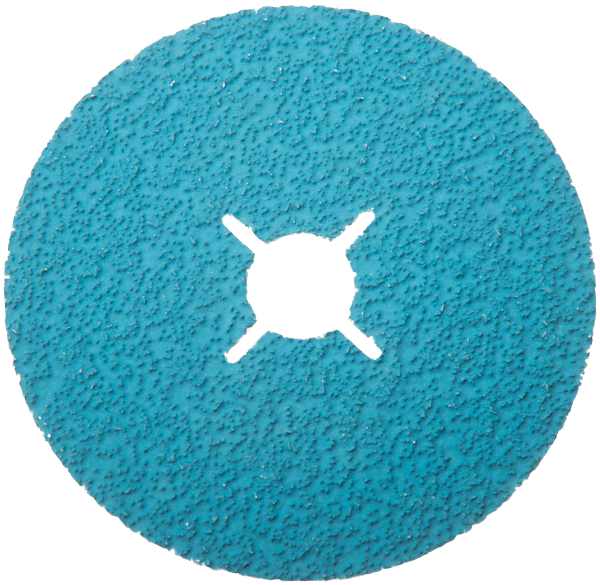

Ceramic

AF890

This powerful ceramic fiber disc is used for the strong and efficient grinding away of heavy welds on flat or slightly curved surfaces.

Order here

Performance

FPC

Our Performance FPC flap disc is used for removing weld seams while maintaining control and achieving a clean transition to the surrounding material.

RCD

The RCD is a compact and aggressive flap disc designed for the rapid removal of local welds and to create a smooth finish.

Order hereCustom solutions

Cibo manufactures grip discs fully customized, in any desired diameter and with custom hole patterns for dust extraction. Thanks to in-house production, we deliver quickly and flexibly.

Custom solutions

Your idea, fully customized.

Discover the possibilities.

75+ years of expertise

Why choose Cibo?

Our high-quality abrasives are designed to meet the specific requirements of the tank manufacturing industry.

Cibo offers specialized abrasive solutions for the tank manufacturing industry, based on over 75 years of experience in grinding and finishing applications.

They provide precision and reliability for critical tasks such as surface preparation, deburring, polishing, and finishing complex tank components.

Customer Case: Ellimetal

Ellimetal is a company that specializes mainly in the production of pressure vessels for the petrochemical sector and storage tanks. They use Cibo’s flap discs, which are primarily used for deburring and rounding off sharp edges, especially in relation to coatings.

Contact

Our abrasives expert in the tank manufacturing industry

Contact100% Belgian

Rebel One Unitized

With over 75 years of experience, we proudly consider ourselves experts in sanding, grinding, and polishing, including within the aerospace and turbine industry.

Rebel OneOur products, particularly the Rebel One Unitized line, are used for grinding turbine blades and other engine components. Manufactured with high precision in our own facility in Belgium, they not only meet the stringent requirements of the aerospace sector but also help shape these standards.

Other industries in which Cibo is active

Marina construction

More information

The Cibo team is there for you

Cibo is at your service with expert advice on sanding, grinding and polishing.

Contact