Aerospace

The future of aerospace

Time-saving abrasives, designed for consistency and reliability in the aerosapce industry

Applications in the aerospace industry

Deburring

Removing burrs from edges and holes and ensuring a smooth finish on machined components.

Surface preparation

Efficient removal of rust, paint, and coatings, and preparing surfaces for welding.

Polishing

Finishing

High-quality polishing for a smooth, shiny finish and surface refinement of automotive and aerospace and aviation components.

Specific applications

Application

Removing scratches and casting defects, pre-polishing

When working aerospace components, precision is everything

Scratches, casting defects, or excessive heat during finishing can lead to delays, rejects, or additional costs.

Our S-line offers the perfect combination of power and control. Its low heat generation prevents damage, even on complex geometries. You can easily remove scratches, casting defects, and fine weld seams, achieving a smooth, glossy finish that meets the strictest aerospace standards.

Commonly used for: turbine blades, landing gear

Application

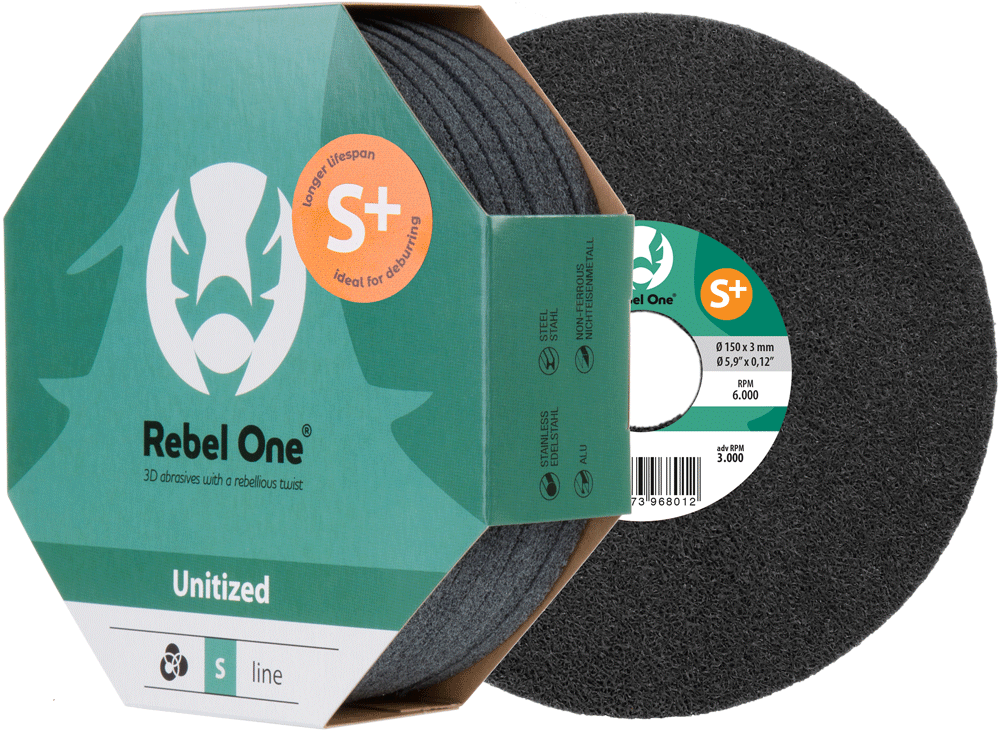

Removing milling lines and welds, deburring

Stubborn milling lines, welds, or burrs can damage the surface and require additional finishing.

Our M-line offers the ideal solution for this. With a more aggressive action than the S-line, it quickly and controllably removes milling lines, light weld seams, and burrs without generating excessive heat.

Thanks to its flexible design, the M-line adapts to complex shapes while maintaining finish control. It is also suitable for finishing screw heads, edge breaking, and grinding exotic alloys for safer, more efficient processing.

Commonly used for: tracks, landing gear

Application

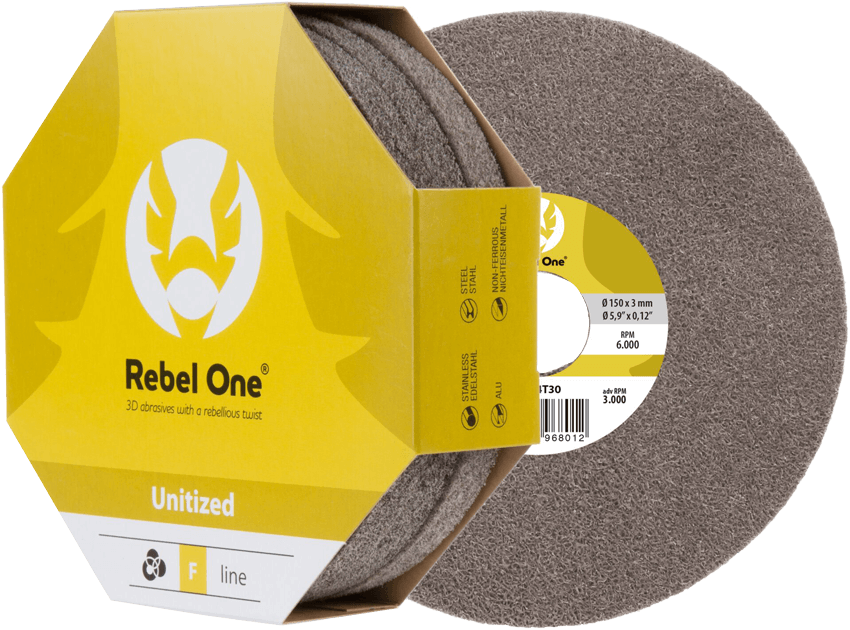

Removing weld discoloration, paint, and coatings; structuring

When cleaning and preparing aerospace components, it is essential to thoroughly clean surfaces without damaging the metal

Traditional abrasives often cause wear, heat, or smearing, resulting in higher costs and shorter tool life.

The F-line is an environmentally friendly, cost-efficient solution that quickly removes weld discoloration, paint, and coatings without damaging the metal. By preventing smearing, tools last longer and grinding costs are reduced.

At the same time, the F-line ensures a precise, consistent surface texture in line with the strictest aerospace standards, making it a reliable and time-saving choice.

Commonly used for: aircraft/helicopter fuselage

75+ years of expertise

Why choose Cibo

Our high-quality abrasives are designed to meet the specific requirements of aviation manufacturing

Cibo offers specialized abrasive solutions for the aerospace industry, based on over 75 years of experience in grinding and finishing applications.

They provide precision and reliability for critical tasks such as surface preparation, deburring, polishing, and finishing complex aerospace components.

Our products specifically for the aerospace industry

Application: deburring

Cibo Bristle

Cleaning or deburring highly irregular or hard-to-reach surfaces without deforming the workpiece

Order here

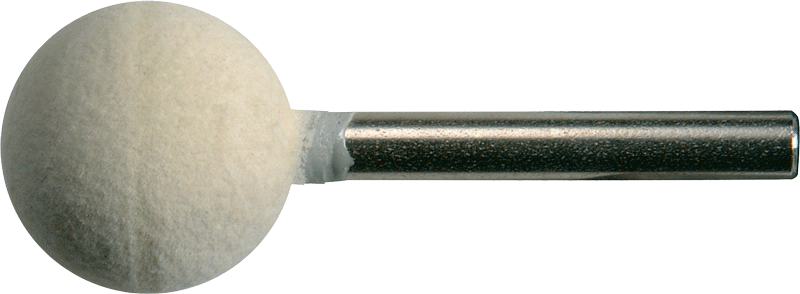

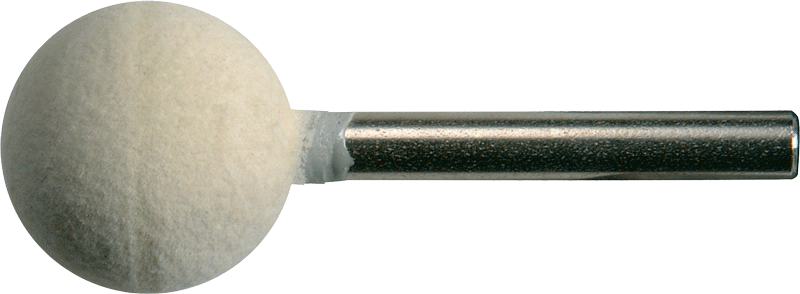

Mounted points

Mounted points designed for blending, deburring, and finishing engine components

Order hereApplication: surface preparation

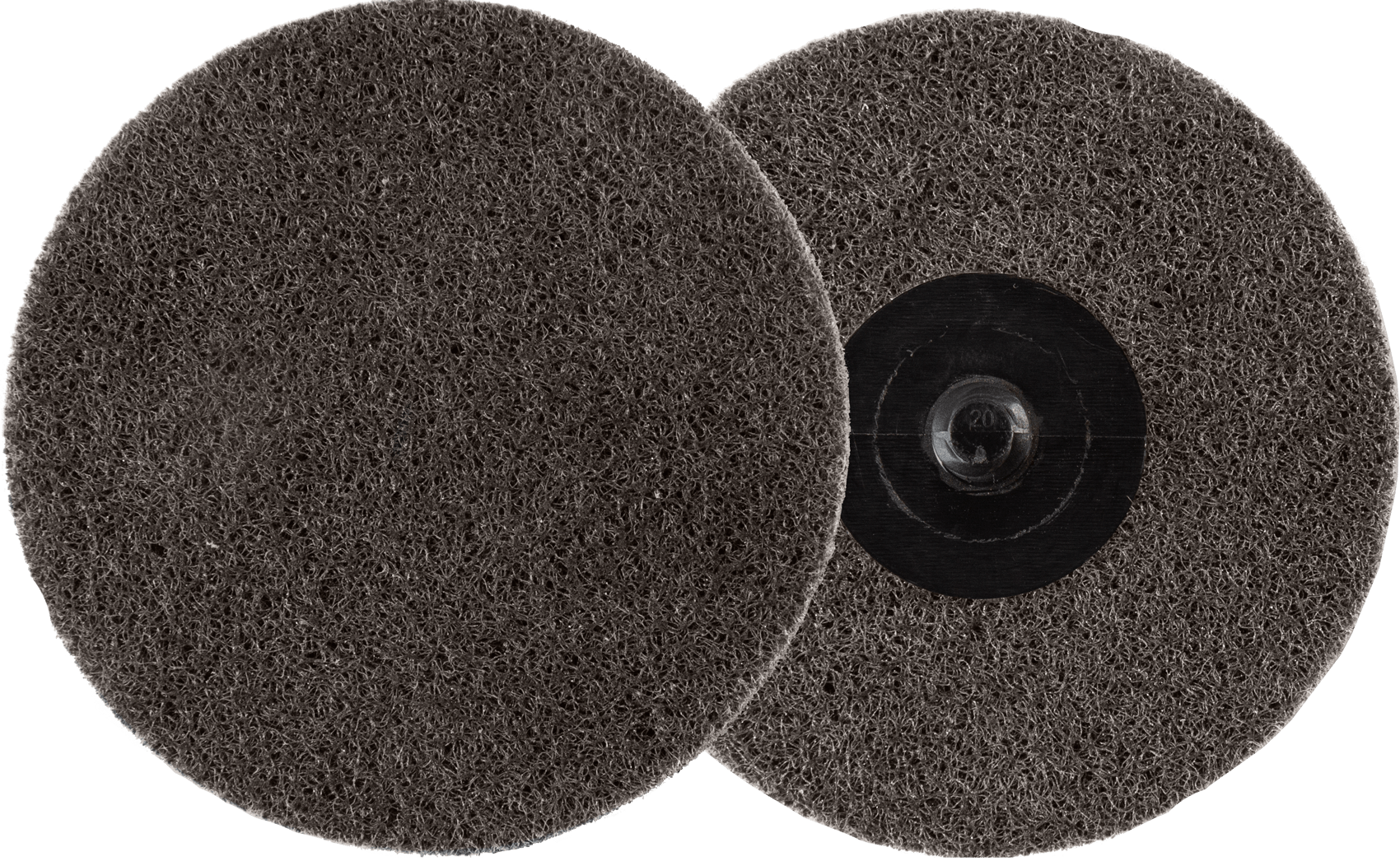

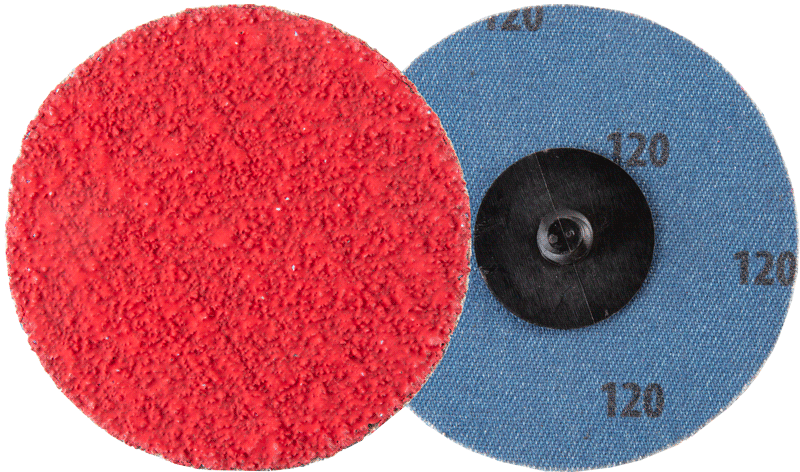

Quick Change

QLPP

For removing light weld seams in hard-to-reach areas. Also effective for removing milling marks.

Toepassing: polijsten & afwerken

Mounted points

Mounted points are designed for blending, deburring, and finishing engine components

Order hereCustom solutions for specific challenges

Every aerospace component presents its own specific challenges, but thanks to our extensive experience, we are able to provide custom solutions that perfectly meet your needs.

Contact us and let us demonstrate our expertise.

Contact

Our expert in the aerospace industry

ContactCase

Finishing aerospace components

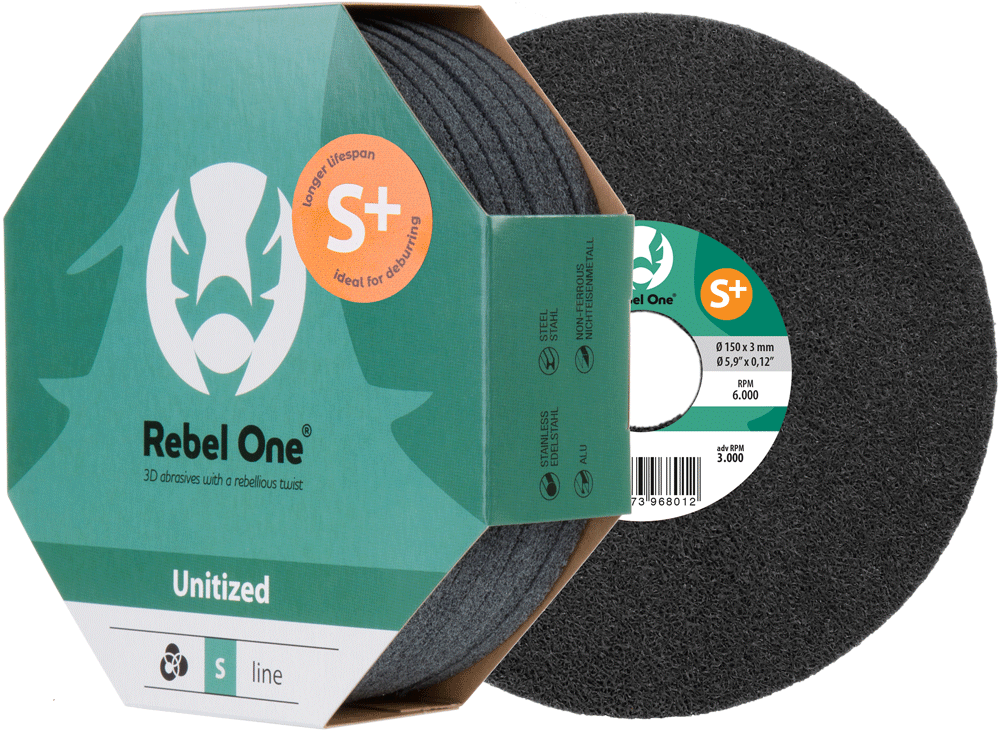

“As a supplier of high-quality aircraft components, finishing is crucial for us. Thanks to Cibo’s abrasive sleeves and Rebel One Unitized lines, we consistently achieve a high level of finish.

The durability and control of these products ensure a more efficient process and fewer reworks.”

Contact our expert

Curious how Cibo can support you?

100% Belgian

Rebel One Unitized

With over 75 years of experience, we proudly consider ourselves experts in sanding, grinding, and polishing, including within the aerospace and turbine industry.

Rebel OneOur products, particularly the Rebel One Unitized line, are used for grinding turbine blades and other engine components. Manufactured with high precision in our own facility in Belgium, they not only meet the stringent requirements of the aerospace sector but also help shape these standards.

Other industries in which Cibo is active

Tank construction

Orthopedic

Marina construction

Robotics

More information

The Cibo team is there for you

Cibo is at your service with expert advice on sanding, grinding and polishing.

Contact